When technology meets tradition, innovation becomes a tool not only for business, but for cultural preservation. At the heart of this intersection stands Mehdi Harrak, architect, entrepreneur, and co-founder of Tech In Hand – Morocco’s first 3D printing company. Here sustainable materials, cutting-edge fabrication and centuries-old Moroccan craftsmanship come together to shape the future. During our visit to the Tech In Hand workspace in Agadir, we saw firsthand how this Orange Corners Morocco graduate is reimagining what’s possible with natural waste materials, transforming them into unique, locally-rooted design products.

Hi Mehdi! Could you introduce yourself and your business, Tech In Hand?

My name is Mehdi Harrak, I’m an architect, entrepreneur and the co-founder of Tech In Hand. Tech In Hand is specialised in 3D printing. Through our products, we give new life to local, natural waste materials. We do this together with the nano composite and composite polymers laboratory of Ibn Zhor University. They produce the printing materials, Tech In Hand does the designing and the printing.

Our goal is to turn waste materials into affordable design products. Argan shells for example, which are left over after the argan oil is sourced. I keep an open mind when it comes to material choices; depending on the project, one material may be better suited than another. Still, I always strive to prioritise the use of the most organic materials possible.

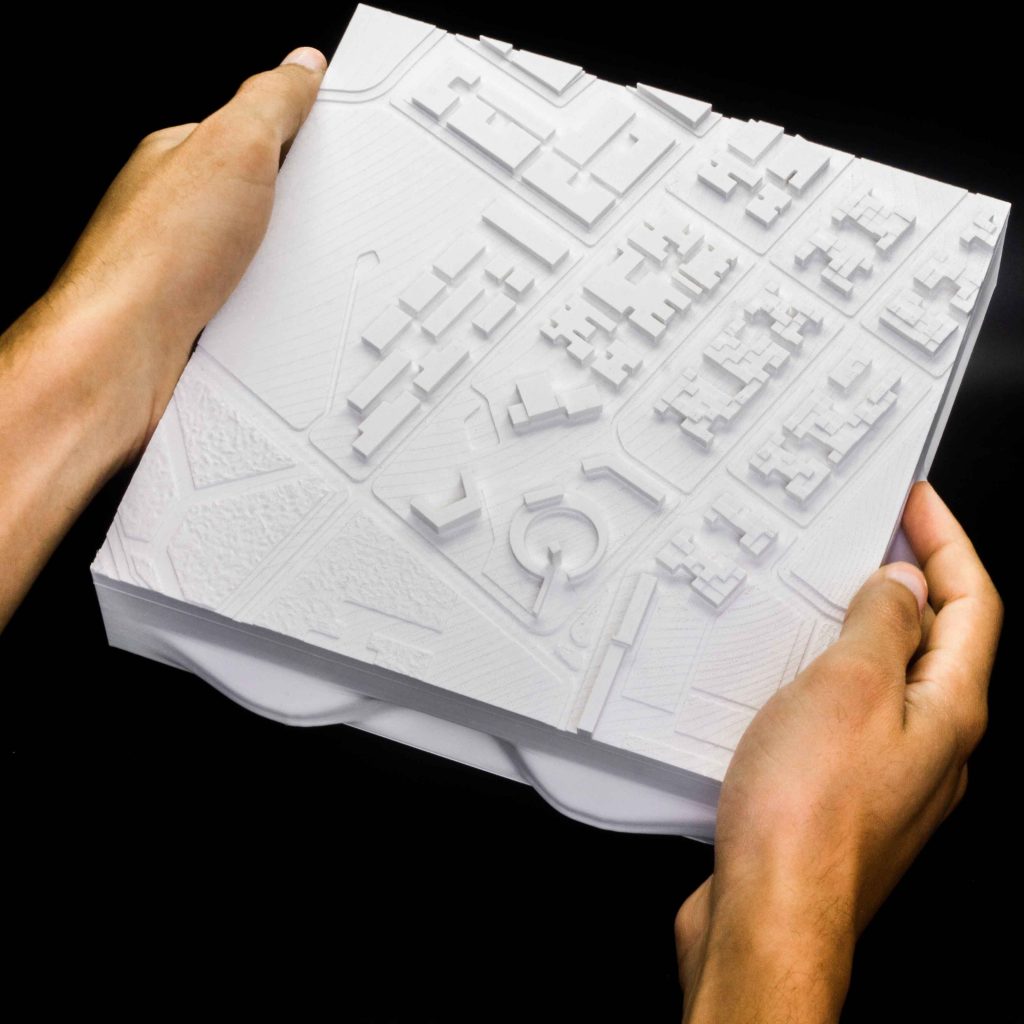

We usually design on demand. Our clients could be anyone really. We worked with construction companies, architects, even museums. A typical process starts with a client approaching us with a request for an object to fabricate. We meet to discuss their needs, draw some concepts in which we try to bring out features unique to his business, and finally bring the project to life through our print farm.

Using 3D printers, we can produce almost anything, from small cups to a wall of any size. My record? I once printed a wall 8 metres long, consisting of 192 different panels!

We really used OCIF to experiment with a new printing technology, going a little bit outside of our previous offering

Speaking of the print farm.. you just finished Orange Corners, but you’ve got quite a machinery set-up here already. What did Tech In Hand look like when you started the programme?

Tech In Hand was already profitable and operating for over a year when we entered the programme. And every time we finished a project, we invested a little back into our business. While 3D printers can be expensive, after just a few successful projects they essentially pay for themselves.

When we started Orange Corners, we already had some printers here, but some are also new. One of them is an OCIF investment, for example. Winning the Marrakech edition of Orange Corners allowed us to get a different type of printer, that before we didn’t have the funds for yet. We really used OCIF to experiment with a new printing technology, going a little bit outside of our previous offering.

Our next machine is going to be a custom-made machine, made by another Orange Corners incubatee – Moroccan Machinery. This will enable us to print larger objects than available commercial printers allow, as well as using different types of materials, like clay. While we already print with clay today, our goal is to collaborate with local artisans and showcase how technology can help reimagine the future of pottery. And we won’t stop there technologically. Our next step will be to invest in a robotic arm, which will provide us with a much greater degree of freedom in both what we print and how we print it.

Besides the printer itself, what we really gained from Orange Corners is a new way of looking at our business. Things like how to set prices, manage cash flow, define and stick to an investment plan, and build the right partnerships. We also learned how to use the sustainability aspect of our work as a real driver for bigger and more ambitious projects. And then there’s the value of having a strong local community. We’ve already collaborated with some of the businesses from our cohort. For example, we designed the walls for the Mosaic Workshops offices, but we also printed Moroccan dolls for YTO Doll using our resin printer. Resin printing is a fascinating process: it starts with a liquid photopolymer resin, which is cured layer by layer with UV light to form a solid object. Watching something materialise like that for the first time always feels a bit magical, almost meditative.

Isn’t it terribly expensive to 3D print a doll, in comparison to regular production?

It would be expensive if you’d sell at a large scale, but for small businesses this is actually really appealing. It helps them to test ideas very fast and make changes based on that in the design phase. If Doae (YTO Doll) wanted a different design tomorrow, we can do that. Of course, once demand grows significantly, it often makes more sense to shift toward more industrial production. That said, many design businesses today are intentionally moving in a different direction, offering smaller, unique batches instead of streamlined, standardised products often manufactured abroad. It’s a way of keeping design more personal, flexible and locally grounded.

Another benefit of 3D printing is that it doesn’t leave any waste, as opposed to subtractive fabrication. It’s the opposite of trends like fast fashion, which leave a lot of waste. Yes, it might be a bit more expensive, but it also gives you the ability to only use what you need and provide your clients a more sustainable product.

We want to go beyond just making money and use our technology to contribute to Morocco’s material heritage

So after this new printer, what’s next for you? Where do you see Tech in Hand heading in the next few years?

We’re planning to expand both the team and the space. It’s been quite difficult to juggle everything myself, being the commercial guy, being the money guy, being the actually guy who prints, models, designs, meets the clients. We’ll have some people that’ll hopefully join the company soon. And we’re also planning to open a second location in Marrakech, with 16 other printers. Those will be used more for B2C markets. Vazes for example, which we think have a lot of potential. These days people want unique objects, and it’s more and more difficult to find something unique in the sea of imported products. That’s exactly what we’re trying to offer, something that’s unique, interesting.

Of course Tech In Hand is a business, and we’re lucky that it’s making us money, but we want to go beyond that and use our technology to contribute to our country’s material heritage. Morocco has such a rich cultural heritage, but unfortunately there’s a disconnect between what’s happening now in construction and design and that heritage. Technology can help bridge that gap, and we want to be part of that movement. For example, we can 3D print architectural elements for housing that resemble traditional construction methods, things like, ceilings, and other components. Printing an entire house using this technology is possible, but not very efficient at the moment. That said, I had the chance to be part of one of the first large-scale 3D-printed clay architecture projects in Barcelona (Spain), which showed what’s achievable on a bigger scale.

In Morocco, we were the first 3D printing company. With Tech In Hand, we’re part of a global digital craftsmanship movement. Although 3D printing was invented in the 1970s, only in the last decade or so we’re seeing real applications in design, in sports, in architecture, in medicine.

It’s exciting to be part of that movement. I like looking at the modern context and figuring out how elements that maybe haven’t changed shape in centuries, what new ways can we think of that’ll allow them to also be part of the future heritage. Finding ways in which technology can take from, but also benefit our heritage.

For example, we recently collaborated with a foundation in Rabat specialised in safeguarding Moroccan cultural heritage. They asked us to analyse a motif, to understand the guidelines behind the motif, create a script that can generate exact replicas – not just the visual aspects, but the rules behind it… which we later used to create puzzles for both children and adults, to learn about their heritage. And at the same time, we safeguard knowledge of the rules that were thought out a long time ago.

With your focus on Moroccan heritage, do you also have ambitions beyond Morocco?

There’s a large market for 3D printing globally, specifically design, elemental, architectural elements and people around the world are attracted to Moroccan art and heritage. We don’t just want to build a name for ourselves, but also find ways to bring Morocco’s visual identity to the world. To do that, we’ll for sure also want to enter other African and international markets. But we’re not quite there yet. Right now, we focus on being really deeply rooted in Moroccan heritage first.

Follow Mehdi’s journey: